Numerous industries utilize CNC machining to produce custom-designed parts for specific projects. The range of CNC materials is used by consumers, engineers, contractors, and other professionals who require specialized solutions for particular applications such as aerospace, electronics, healthcare, and much more. In it, the key is to choose the right materials. Many CNC materials come under two major categories: metals and plastics. This article will compare the two while discussing their advantages and possible applications.

An Overview of CNC Machining

CNC, or Computer Numerical Control, is the automated specialized machinery that removes material from the stock piece and turns it into a custom-designed component. It differs from 3D printing, and the computer software that aids the movement of machinery is often computer-aided design (CAD). Instead of adding material layer by layer to create a part, this strategy involves removing material from a blank to achieve the desired final form. CNC machining enables the completion of three-dimensional cutting tasks using a single set of instructions.

Two Major CNC Material Categories

CNC materials pertain to unprocessed substances or workpiece materials manipulated and altered using Computer Numerical Control (CNC) equipment. However, choosing the best CNC material for your project can take time because it requires a thorough understanding of its advantages and uses. Read on as we discuss and compare two necessary CNC materials for your next project.

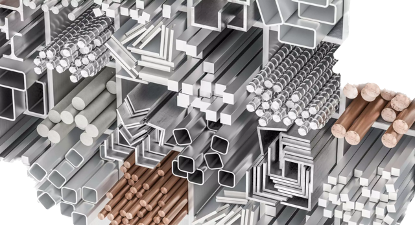

Metal CNC Materials

Metal is the most commonly used CNC material because of its durability, robustness, and heat resistance. It has become the cornerstone of creating powerful tools and caused remarkable developments in CNC machining, whether for creating prototypes or engineering models. You might choose one of these popular metals depending on your project:

Titanium

Titanium is an advanced material with a substantial strength-to-weight ratio, corrosion resistance, and biocompatibility. Due to its invaluable properties, it is now a preferred material in medical aesthetics, high-performance automotive parts, and the aerospace industry.

Carbon Steel Alloys

Carbon steel alloys contain 0.03-2%[1]carbon content. Steel perfectly balances cost and functionality due to its ease of machining and welding. Due to its susceptibility to rust, numerous techniques have been developed for its CNC surface finishing. These alloys are highly preferred for their cost-efficiency and suitability for applications that demand durable components, such as construction materials and heavy-duty machinery parts.

Magnesium

Magnesium is also an excellent and common CNC material if safety guidelines are followed because it tends to ignite or explode. It offers robust machinability and manufactures high-strength and lesser-weight material parts. It also requires a lower cutting force and is widely used in automotive manufacturing and aerospace industry.

Plastic CNC Materials

Plastic CNC Materials are preferred for creating parts requiring less weight, excellent corrosion resistance, and lower costs. They have been used in the production of electronics, healthcare, and food processing industries. Plastics can present challenges when it comes to machining. However, their lightweight nature and simple geometries often make them a better machining choice[2] than 3D printing or injection molding.

Let’s explore some of the most accessible and widely used plastic CNC materials in the world of custom-designed components:

Nylon

Nylon is highly regarded in the selection of plastic CNC materials due to its strength, adaptability, and resilience against abrasion. Commonly utilized in CNC machining, it is used in gears, bearings, and components that necessitate a precise combination of strength and flexibility.

LDPE

LDPE, or Low-density polythene, offers excellent moisture resistance and boasts superior malleability and formability compared to other types of polyethylene. It is not only affordable but also provides temperature stability and is used in sliding rails and gibs[3], requiring low temperature and more flexibility.

Comparison: How to Choose between Medal and Plastic CNC Materials?

Choosing between metal and plastic CNC machining materials is a crucial process, but let’s get into it and compare the two for your ease:

Machining Processes

Metal machining encompasses a range of exact processes, including precision milling, turning, and grinding. You can effortlessly slice through solid metal by employing these cutting-edge techniques, leaving precise chips and shavings behind. However, plastic machining typically encompasses milling, turning, and drilling processes. Although less heat resistant than metals, plastics can still pose challenges during machining processes.

Physical Properties and Costs

Metal CNC materials are renowned for their exceptional strength, durability, and impressive heat resistance. Although they cost more than plastic, these products are worth it when durability and longevity are important. Plastics are affordable, corrosion-resistant, and versatile. These properties make them ideal for projects requiring weight loss and cost control.

Applications

The applications of metal CNC materials span the aerospace, automotive, and medical sectors, where precision and reliability are sought. However, plastic CNC materials often find their niche in consumer goods and medical devices.

CS Mold: A Reliable Choice

At CS Mold, we take pride in our comprehensive range of CNC materials, encompassing various plastics and metals such as magnesium, aluminum, premium plastic materials, and more. These materials are sourced from our trusted suppliers, who undergo rigorous evaluations, ensuring a consistent and reliable stock readily available for our projects.

Beyond standard offerings, we specialize in providing super-hard alloys and tailored options to meet unique project demands. Our team of engineers is dedicated to guiding material selection for you, ensuring the perfect fit for your demands. Moreover, we also uphold stringent regulatory standards, and our inspection lab utilizes cutting-edge tools, like Raman spectroscopy, to meticulously verify the chemical and physical attributes of each batch. With our commitment, you can trust us and believe that every material used in CNC machining projects meets uncompromising quality and compliance standards.

Conclusion

Understanding the differences between metal and plastic CNC materials helps highlight how vital CS Mold is to precision CNC machining services. With over 10 years of experience in CNC machining, We, CS Mold, are a prominent CNC service provider who can offer a wide range of material expertise, sophisticated machining techniques, and a dedication to timely and cost-effective solutions. Elevate your CNC machining experience with us today! If you have any questions about CNC service, please contact us!

Reference

[1] Available at: https://www.worthyhardware.com/cnc-machining-steel-materials/#:~:text=What%20is%20CNC%20Machining%20Steel,carbon%20steel%20and%20alloy%20steel.

[2] Available at: https://www.xometry.com/materials/material-cnc-machining-plastic/

[3] Available at: https://zmorph3d.com/blog/ldpe-cnc-machining-materials-overview/#:~:text=It’s%20not%20as%20hard%20than,a%20good%20stability%20to%20temperature.