Rapid Prototyping Service

Rapid prototyping and full-scale production

Tolerances down to ±.0008 (0.020 mm)

Lead times from 3 days

Quotes for up to 10,000 parts

For the past decade, the CS mold technology team has been focused on the research, design, and production of rapid prototype molds, continuously summarizing experience and developing a set of specialized standards for prototype mold production to achieve a balance of quality, speed, and cost for the best interests of customers, minimize costs, to achieve a win-win situation with customers. Over the years, we have helped many startups and established brands to manufacture prototypes and products that are competitive in the global market.

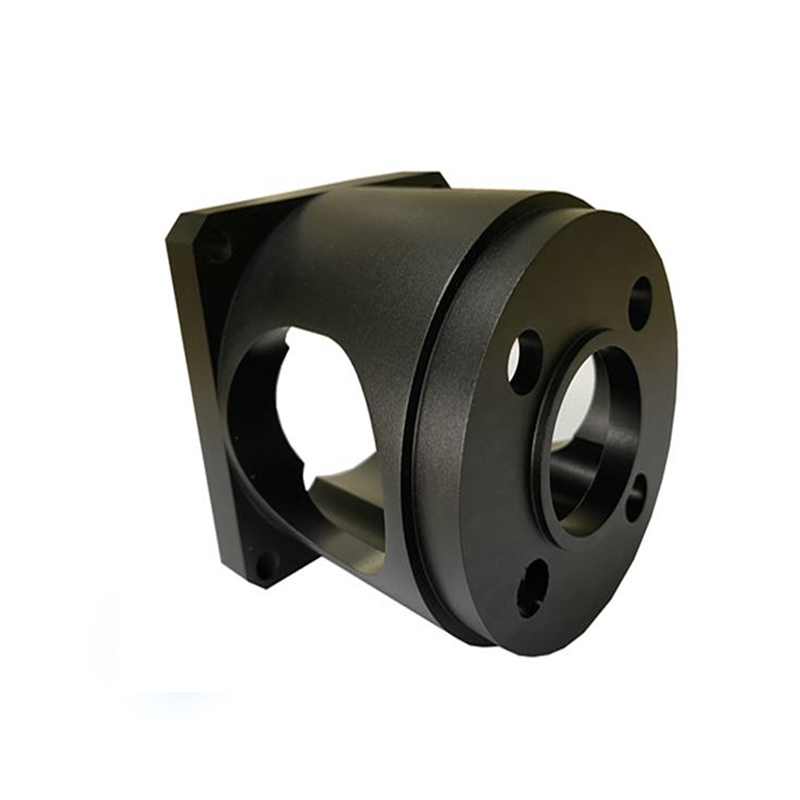

CS Mold, as a china rapid prototyping factory, provides a variety of rapid manufacturing processes that can be used to quickly and economically create prototypes, such as CNC machining, injection molding, sheet metal processing, and polyurethane casting.

CS Mold provides a variety of rapid manufacturing processes that can be used to quickly and economically create prototypes. Such as CNC machining, injection molding, sheet metal processing, and polyurethane casting.

Rapid prototype manufacturing is a fast and economical mold that utilizes modern high-speed and high-precision processing equipment, simplified and reliable mold design solutions, and effective processing procedures to meet part design specifications in terms of accuracy and quality within a short delivery time. Prototypes are typically used to test the feasibility of the design.

With the development of technological innovation, rapid prototyping technology is widely used in product development, creation, and market testing. Compared with traditional molds that are long cycles and high cost, rapid prototyping has more advantages. It not only has fast turnover speed and high cost-effectiveness but also has reliable accuracy and quality. Moreover, it is superior to modern forming processes that are limited by material and accuracy.

With the development of technological innovation, rapid prototyping technology is increasingly widely used in product development, creation, and market testing. Compared with traditional molds with long cycle and high cost, Rapid prototyping has more advantages. It not only has fast turnover speed and high cost-effectiveness, but also has reliable accuracy and quality. Moreover, it is superior to modern forming processes that are widely limited by materials and accuracy.

Rapid prototyping includes various materials that can be used to quickly create prototypes and functional components. The following are some commonly used materials in rapid prototyping:

- Thermoplastics: These materials are very popular in 3D printing, including ABS (acrylonitrile butadiene styrene), PLA (polylactic acid), PETG (polyethylene terephthalate), and nylon. They have good strength, durability, and various mechanical properties.

- Resin: Resin-based materials, like Photopolymer resin, are usually used for stereolithography (SLA) and Digital Light Processing (DLP) 3D printing technology. They provide accurate details, smooth surface finishes, and a wide range of material properties, including options for rigidity, flexibility, and transparency.

- Metal: Rapid prototyping of metals involves using various metal alloys, such as aluminum, stainless steel, titanium, and brass. Technologies such as Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS) can produce functional metal parts with excellent mechanical properties.

- Composite material: Composite material that combines two or more different materials, and is also used for rapid prototyping. For example, carbon fiber composite materials have a high strength-to-weight ratio, making them suitable for lightweight and sturdy prototypes.

- Silicone: Silicone rubber is widely used in manufacturing flexible prototypes, molds, and parts with elastic properties. It is typically used in applications that require durability, flexibility, heat-resistance, and chemical resistance.

- Ceramics: Advanced ceramics, such as alumina and zirconia, can be used for Rapid prototyping of parts with high-temperature resistance, electrical insulation, and mechanical strength.

Design for

Manufacturability Analysis

Provide detailed DfM (manufacturability analysis design) to display all detailed information, including parting line, gate position and size, ejection position, wall thickness, surface finish, tolerances and potential shrinkage marks, gate trace warping, etc.

Mold processing

& Acessories

After approval by DfM, different machines are used to cut and process steel, such as gun drill, CNC, EDM, and wire cutting. Finally, the mold maker collects all the components together for mold assembly and polishing, and prepares the mold before trial molding.

Mold testing and

quality inspection

The molding master prepares and dries the materials to reach the required temperature, and the filling amount of the trial mold ranges from 10% to 110%. Finally, the project engineer inspected and sent the five completed photos to the QC department for quality and dimensional inspection.

Advantage of Rapid Prototyping

Using rapid prototyping technology during the product development phase can help customers fully understand the feasibility of the design, evaluate whether the product meets current market needs, and make adjustments before the products launch on the market. Nowadays, more and more customers recognize and use rapid prototyping technology because rapid prototyping has many advantages.

Reduce product development and costs

Rapid prototyping can quickly and efficiently turn your ideas into reality. Saving time in the early stages of development can help you get closer to the final product and reduce costs, thereby achieving a return on investment.

Test product functionality

The prototype accurately reflects the appearance and operation of your product. Though testing and retesting provide the opportunity to fine-tune your ideas and transform them into the most likely winning design, can it provide a good user experience? Can it achieve your goals? At this point, you can identify features that require more works and identify potential areas for expansion.

Assess and identify potential safety and/or compliance issues with the product

From appearance to functionality, you can identify the root causes of any risk factors involved in the design at this stage. The rapid prototyping process uses a large number of materials, making it easy to find the ideal combination to ensure that your final product achieves your goals.

Listing speed

Rapid prototyping and accurate tools help improve productivity and ultimately enter the market faster than other methods.

Compatibility with multiple materials

CNC machining can be used to process various materials, including various plastics and metals. This makes it an ideal choice for cross-industry rapid prototyping design.

Applications

Rapid prototyping is a commonly used manufacturing process in product development and is popular in many industries. Speed and economy are key principles of rapid prototyping, allowing for the simultaneous production of multiple designs for prototypes, or the rapid and continuous modification and remaking of a single prototype.

WHY CHOOSE US

INSTANT QUOTING

Timely reply and provide the quote within 24 hours

NO MOQ REQUIRED

Hord does not have minimum order quantity

HIGH QUALITY

ISO 9001 & IATF 16949 certificated and inspect every step

COST-EFFICIENT

+30% cost lower than western competitors

QUICK TUAROUND

Parts make in 7 days and delivery on time

DFM ANALYSIS

Once receiving the inquiry, we will provide you with a preliminary DFM report

PROFESSIONAL SERVICES

More than 20 years of rapid tooling making

GOOD RAPUTATION FROM CUSTOMERS

Customers are satisfied with our services, products quality and delivery time.

OUR ADVANTAGE

QUICK TUAROUND

Parts make in 5 days and delivery on time

DFM ANALYSIS

Once receiving the inquiry, we will provide you with a preliminary DFM report

PROFESSIONAL SERVICES

More than 10 years of rapid tooling making

GOOD RAPUTATION FROM CUSTOMERS

Customers are satisfied with our services, products quality and delivery time.

INSTANT QUOTING

Timely reply and provide the quote within 12 hours

NO MOQ REQUIRED

CS Mold does not have minimum order quantity

HIGH QUALITY

ISO 9001 & IATF 16949 certificated and inspect every step

COST-EFFICIENT

+30% cost lower than western competitors

Employees

Satisfied Customers

Production Workshop

Rapid Prototyping FAQs

Rapid prototyping supports a wide range of materials, including plastics (such as ABS, PLA, nylon), metals (like aluminum, stainless steel, titanium), ceramics, and even composite materials. The material choice depends on factors such as the intended purpose of the prototype, functional requirements, and desired aesthetics.

Yes, rapid prototyping can produce functional prototypes that closely resemble the final product. With advancements in additive manufacturing technologies and materials, functional prototypes can simulate the mechanical, thermal, and electrical properties of the end product, allowing for comprehensive testing and validation.

The lead time for rapid prototyping varies depending on factors like the complexity of the design, chosen prototyping technology, size of the prototype, and the availability of materials. Typically, rapid prototypes can be produced within a few days to a couple of weeks, allowing for quick design iterations and evaluation.