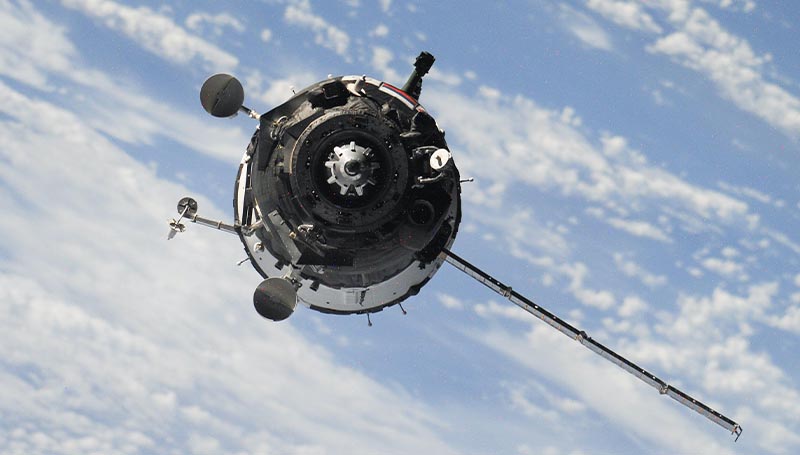

Manufacturing for Aerospace Components

The aerospace industry has extremely high requirements for components, requiring precise specifications as well as the highest reliability and quality standards. By combining technology with internal engineering and manufacturing expertise, CS Mold’s aerospace prototyping service can produce and deliver excellent-quality products and components to meet and exceed clients’ requirements.

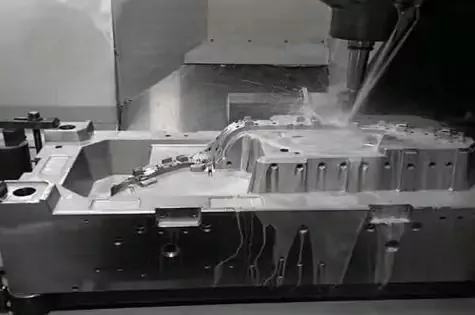

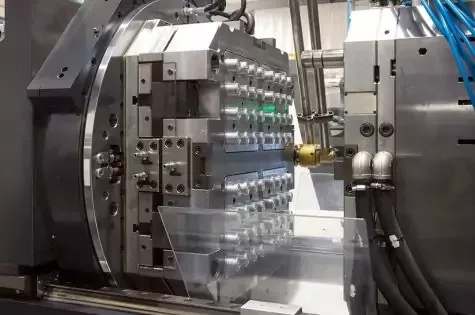

CS Mold uses various processes to manufacture aerospace prototyping products, including CNC machining, plastic injection molding, sheet metal, die-casting, and aluminum extrusion. Unique manufacturing processes and types of equipment ensure the quality, control, and performance of the most demanding operations, including lightweight, high-temperature, low-temperature, and highly corrosive applications.

Services for Aerospace Industry

CS Mold offers various low-volume manufacturing services to help our clients with their prototypes and toolings. Contact us to choose the most suitable one for your project!

Aerospace Industry

WORK WITH US

Step 1

Share the 2D/3D files and project specifications with us for a precise quotation

Step 2

Once the order is confirmed, we will provide a detailed design and manufacturing analysis report. Our engineers will review all tolerances and appearance specifications, identifying any issues that may affect the quality of the parts.

Step 3

Upon DFM approval, we will initiate production. Our project engineers will conduct thorough inspections of the parts’ dimensions, tolerances, and appearance during manufacturing, ensuring they meet your expectations.

Step 4

After the quality inspection, the parts will be shipped to your location.