What is GD&T?

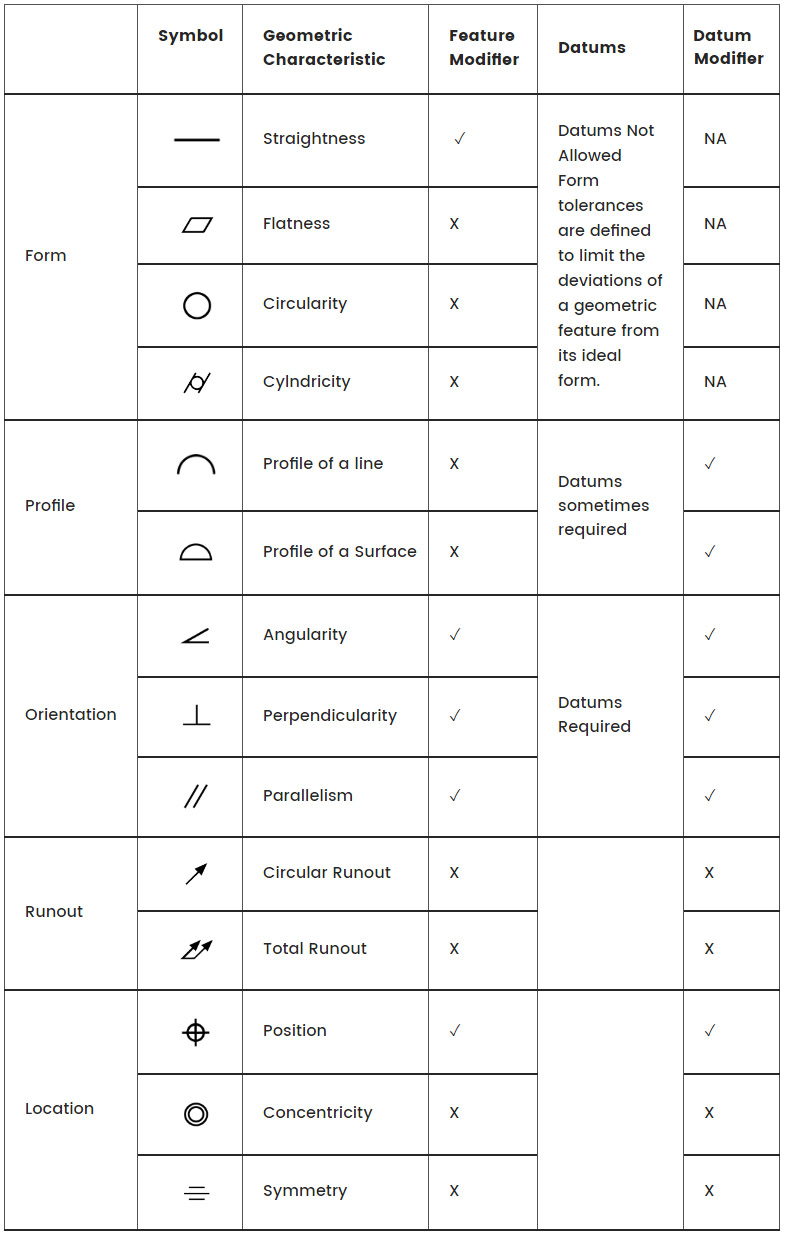

To address discrepancies arising from the manufacturing process, a symbolic language called Geometric Dimensioning and Tolerancing (GD&T) is employed by engineers and manufacturers. GD&T enables better control and communication of these variations.

GD&T serves several purposes:

- It defines the ideal geometry of parts and assemblies, known as the nominal geometry.

- It specifies the acceptable range of form and size for individual features.

- It establishes the permissible variation in orientation and location between features.

Dimensioning specifications focus on defining the intended or as-modeled geometry, often expressed through basic dimensions.

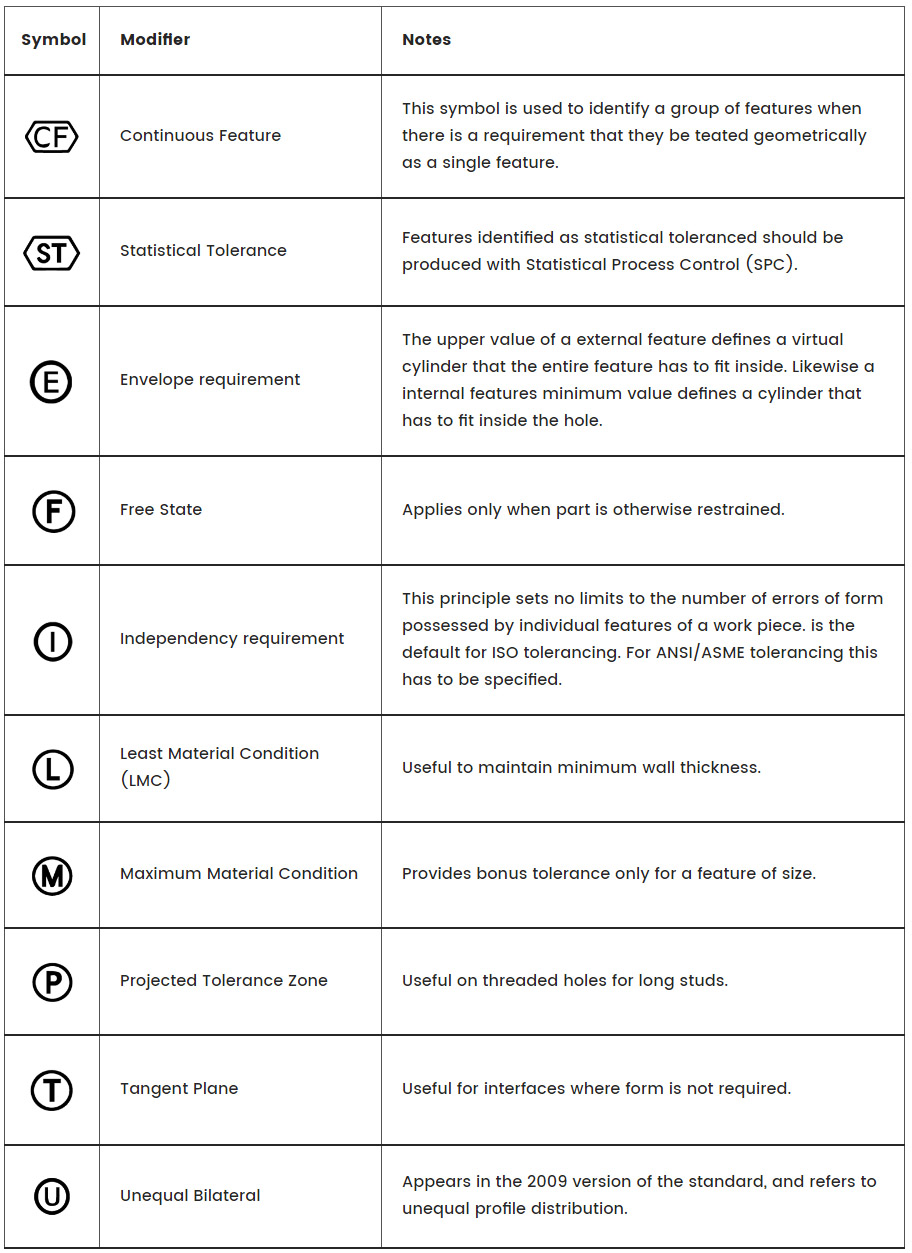

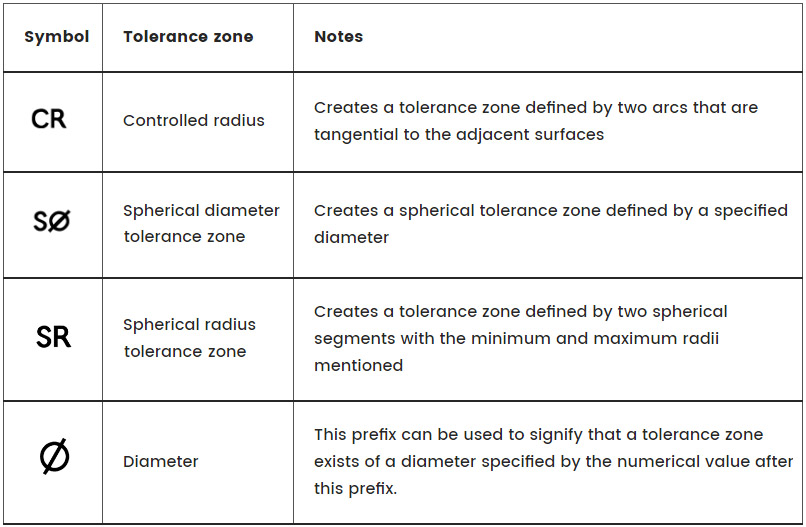

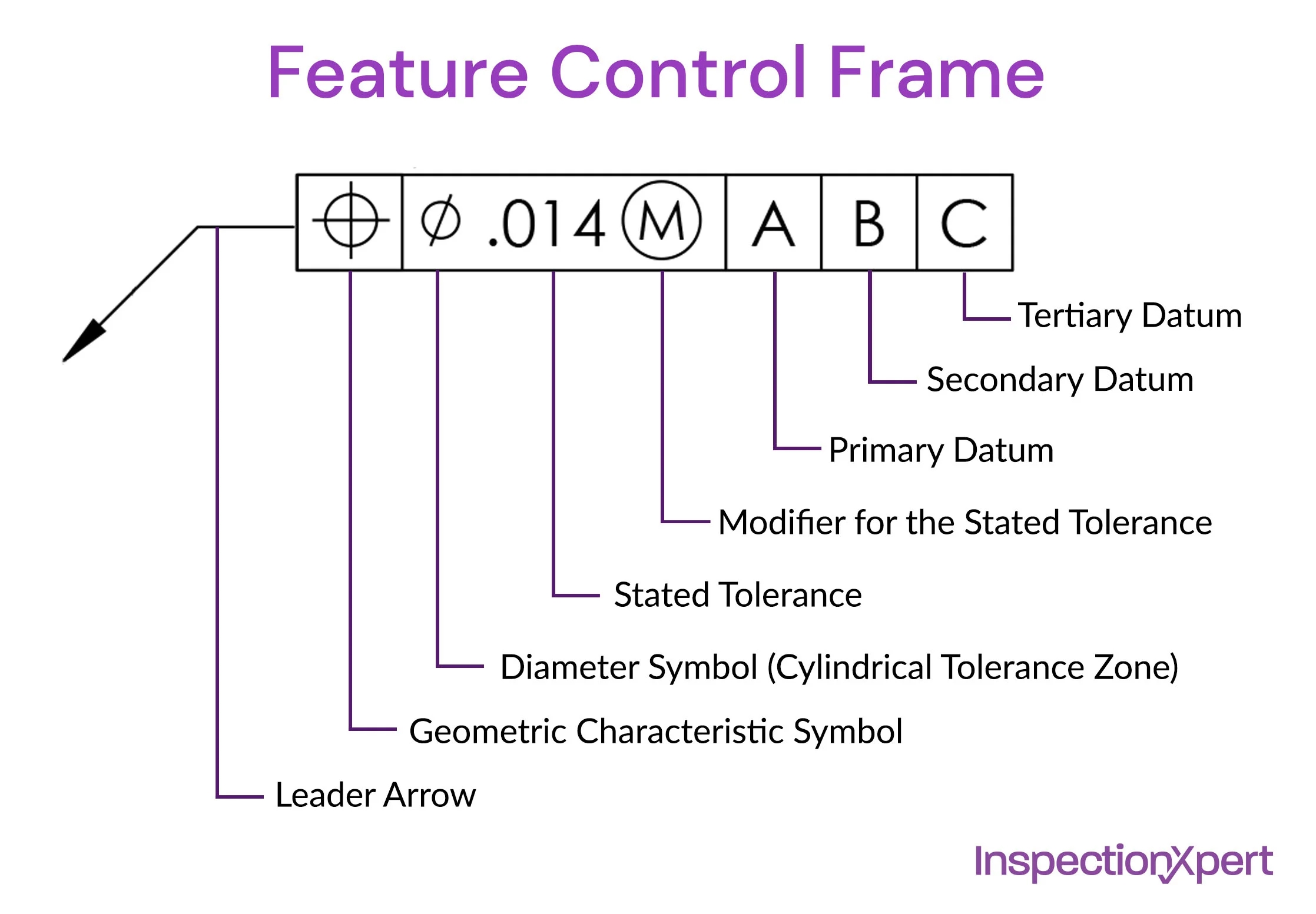

Tolerancing specifications, on the other hand, outline the allowable variation in form, size, orientation, and location of individual features. This includes linear dimensions and feature control frames, which utilize datum references.

By utilizing GD&T, engineers and manufacturers can accurately define and communicate the required specifications, facilitating the production of high-quality and precisely manufactured projects.