As a seasoned expert in plastic manufacturing, CS Mold delves into the nuances of injection molding and compression molding to help you understand the variances between these two pivotal processes. With our wealth of experience and dedication to precision, we shed light on the unique characteristics and applications of each method, guiding you towards informed decisions for your plastic product needs.

At CS Mold, we pride ourselves on being at the forefront of injection molding technology, offering a seamless and efficient process for creating a diverse range of plastic products. With over a decade of industry experience, our team at CS Mold is well-versed in delivering top-tier injection molding services that cater to projects of any scale or complexity. Trust us to bring your plastic product visions to life with superior quality and exceptional attention to detail.

Precision and Efficiency

Injection molding stands out for its precision and efficiency in producing intricate plastic components with minimal post-processing requirements. Our state-of-the-art injection molding capabilities guarantee high-quality parts that meet stringent industry standards, while ensuring quick lead times to accommodate your project timelines effectively.

Versatility and Adaptability

From everyday items like chairs and toys to specialized products such as consumer electronics cases, disposable cutlery, and car body panels, injection molding offers unparalleled versatility in manufacturing various plastic products. CS Mold’s expertise allows us to work with diverse materials and molding techniques to bring your concepts to fruition with precision and reliability.

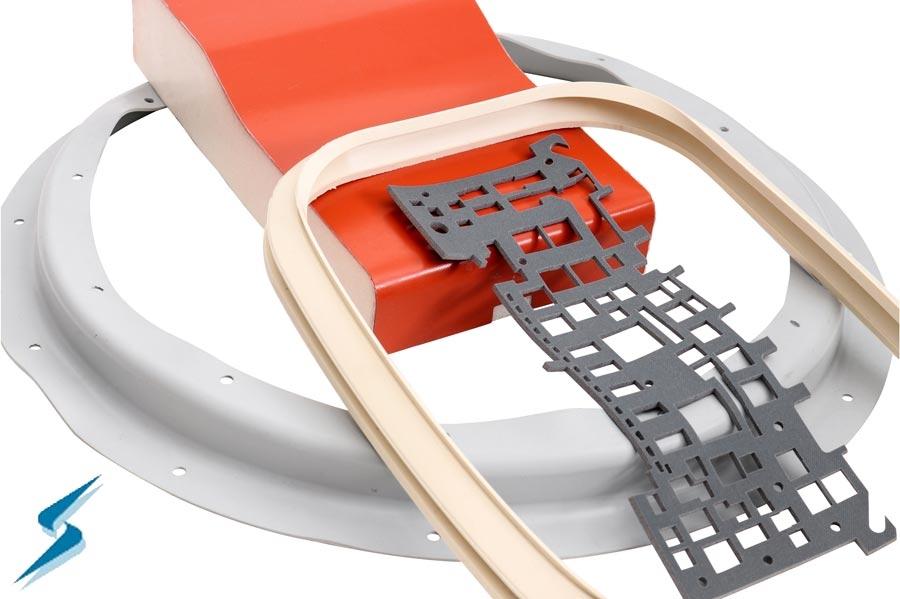

Pressure-Based Process

Compression molding involves applying pressure to heated plastic material within a mold to create the desired shape. This method is suitable for producing thicker and larger parts that require specific structural integrity. CS Mold’s proficiency in compression molding ensures the production of durable components tailored to your unique requirements.

Material Considerations

Compression molding allows for the use of a wide range of materials, including thermoset plastics and composites, making it ideal for applications where material strength and durability are paramount. Our dedicated team can guide you in selecting the most suitable materials for your compression molding projects, ensuring optimal performance and longevity.

Conclusion

In the realm of plastic manufacturing, injection molding vs compression molding is crucial for making informed decisions regarding your product development initiatives. With CS Mold as your trusted partner, you can rely on our expertise in both injection and compression molding processes to achieve outstanding results that align with your vision and requirements. Discover the power of precision and versatility with us injection molding and compression molding services, where excellence meets innovation in every plastic product we create.