Learn about the difference between compression and transfer molding in this article, with a focus on silicone compression molding. This technique offers an efficient and straightforward approach to creating high-quality silicone rubber parts, thanks to its precision manufacturing of compression molds. CS Mold is a leading player in silicone compression molding, offering expertise and innovative solutions to help businesses navigate these differences and deliver top-notch components.

An In-depth Look at Silicone Compression Molding

Silicone compression molding, in comparison to its counterparts such as LSR injection molding, silicone transfer molding, or extrusion molding, stands out for its inherent simplicity and efficiency. This molding technique involves a meticulous process that distinguishes it from others in the industry.

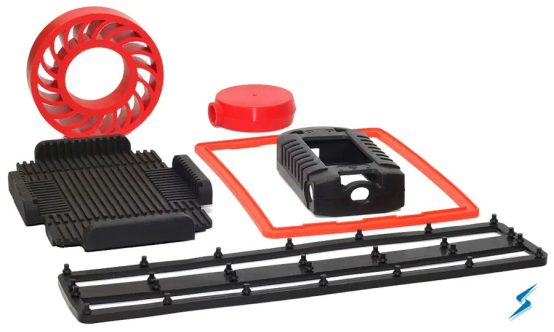

At the heart of silicone compression molding lies its straightforward approach. The process begins with the manufacturing of compression molds through advanced techniques like CNC machining and polishing. Unlike other molding methods, silicone compression molding often utilizes a two-plate mold, comprising the cavity side and core side. This unique design enhances the efficiency of the process and allows for the creation of diverse silicone rubber parts.

Delving into the steps of compression molding unveils the precision involved in crafting silicone components. The CNC machining and polishing stages ensure the molds are meticulously crafted, laying the foundation for a successful compression molding cycle. The two-plate mold design further streamlines the process, making it a preferred choice for businesses seeking a balance between simplicity and effectiveness.

CS Mold’s Expertise: Navigating the Complexity of Silicone Compression Molding

CS Mold takes center stage in the silicone compression molding landscape, bringing a wealth of expertise and proficiency to the table. Our role in the industry is marked by a commitment to navigating the complexities of silicone compression molding with finesse.

As a leading player, CS Mold excels in the manufacturing of compression molds through CNC machining, ensuring precision and consistency. Our proficiency in this crucial stage of the process sets the stage for a simplified yet highly effective silicone compression molding process. We understand that each component matters, and our expertise ensures that every silicone rubber part meets the highest standards of quality.

CS Mold’s commitment to excellence extends beyond the manufacturing floor. We are not just providers of compression molding services; we are partners dedicated to delivering innovative solutions. Our expertise ensures that the silicone compression molding process remains efficient, offering businesses a reliable method for producing high-quality components.

Conclusion

To sum up, the difference between compression and transfer molding are vast, with silicone compression molding emerging as a simple yet powerful technique. CS Mold’s expertise in this domain ensures that businesses can navigate these differences seamlessly, leveraging the advantages of silicone compression molding for their unique applications. Choose CS Mold for a partner that decodes the variances and delivers unparalleled excellence in silicone compression molding.